ARTICLES

GAS METER TOP CONNECTIONS (DIAPHRAGM TYPE METERS)

by Paul Devlin

Posted by Devtech

Terminology between the manufacturers of domestic and commercial meters has in some cases confused the end user and some in the distribution / order entry network. This will be an attempt to help all who order, code, specify or quote meters.

In top connect meters (Photo 1) part of the casting has usually a male threaded fitting permanently affixed to the meter. Some call this threaded part the spud, some the meter connection threads.

Photo 1

This meter connection thread has numerous thread configurations from 5 lt. to 100 lt. with many in between: such as 10 lt., 20 lt., 30 lt., 45 lt., 60 lt. as well as 1 1/4" (alias Pitts #0) 1A and 2A. This meter connection threads must match the swivel nut which is next to be explained.

A swivel nut, or meter cap, also has the same size designation as the meter connection thread (or spud): 5 lt. thru 100 lt. and all sizes in between as mentioned in the above paragraph (see photo 2).

Photo 2

So now we look at the most maligned part of the set up, the swivel (photo 2). It has been called meter connection thread, spud, meter top, nut size and whatever: this confuses us all from time to time (in my 40 years in the industry, I have got it wrong more than once).

Swivels, the piece of pipe that connects the meter to house piping for the customer: from 1/2" to 2" in size. Most swivel ends have male pipe thread at the end but there are a few with female pipe ends so the usual designation is used here (MPT or FPT). Also the end opposite the threaded end must fit the meter connection thread (spud) and be accommodated by the meter cap (nut).

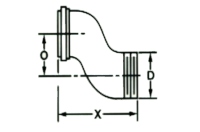

So, we will have a meter swivel that could have 3/4" threads on one end (FPT or MPT) and 10 lt., 1A, 20 lt., 30 lt. 1 1/4" (Pitts #0) configuration on the other end. To add one more possibility, the swivel and nut combination could be insulated (one side insulated or both sides insulated) (photo 3). The swivel is the part insulated where it mates with the cap (nut). Some swivels are called reducing swivels because their normal size is say 20 lt. by 1" MPT, but can be obtained as 20 lt. x 3/4" MPT (thus reducing swivel).

Photo 3

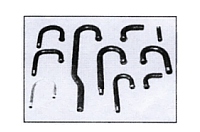

For many, especially in some of the gas systems that used tin case meters, offset swivels are available and the same considerations as above must be taken into account (photo 4).

Photo 4

Specifications have requirements for galvanized swivels and caps or plain black iron cast swivels. Now we are seeing more extruded, or coined meter swivels, these may be plain steel or epoxy coated (photo 5).

Photo 5

These manufactures that have purchased special machinery and now can make many swivel confirmations to assist the gas company with their meter sets offering a variety of configurations (see photo 5). Many find these benefits economical to install and in many cases the fewer fittings and elbows, mean a more attractive meter set, less chance for atmospheric corrosion, with fewer possible leak paths.

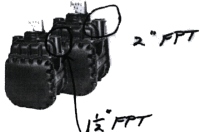

A few of the large meters have simple female pipe threads in the top of the meter (meter connection threads or meter spuds); these are the commercial meters like the AL1000 / 800 (photo 6). Here the house piping is fitted directly to the female pipe thread with a union usually located in close proximity for ease of servicing the meter.

Photo 6